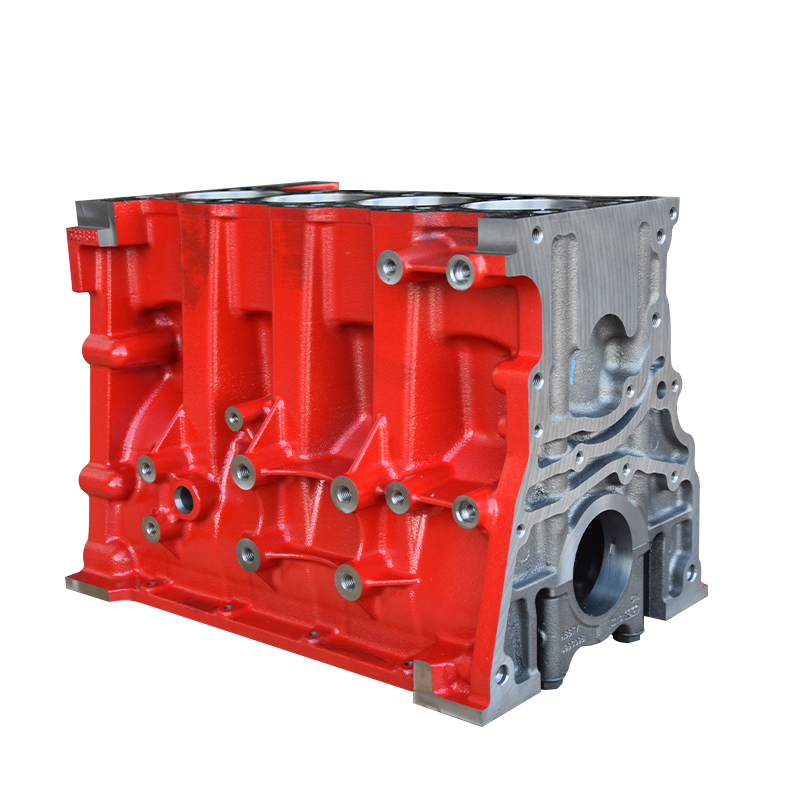

Cummins ISF2.8 Engine Crankshaft 5264231

OE Part No:5264230/5264231/5340179/5282791/5443207

Truck Engine Crankshaft

The crankshaft of an internal combustion motor is the component that converts the upward and downward motion of the pistons to rotary motion. The crankshaft is usually made from aluminum or steel reinforced to withstand high forces generated by combustion. The connecting rod connects the crankshaft to the pistons and transfers the power generated by combustion to the wheels.

| Product Name | Cummins ISF2.8 Engine Crankshaft 5264231 |

| Brand | Cummins ISF2.8 |

| Quality | Original/OEM/Aftermarket |

| Material | Metal |

| Application | Agriculture/Construction/Marine/Mining/Bus/Trucking/Defense/Municipal Services |

| Engine Type | Diesel |

| Warranty | 6-12month |

| MOQ | 1 Piece |

| Payment | TT/LC |

| Lead time | 3-7days |

What’s an engine crankshaft?

The main rotating component of an engine is the crankshaft. The connecting rod can be installed to accept the reciprocating (up and down) movement of connecting rods into a rotating (cyclic) movement. The main journal and connecting rod are two of the most important parts. The materials used for these components include forged steel or aluminum. The main journal is mounted on the cylinder, the connecting neck is attached to the large end hole of the connecting rod, and the small hole is connected to the cylinder piston. This is a crank slider mechanism.

Common Damage to Engine Crankshaft

Engine Crankshaft damage can take many forms, including wear on the journal, torsion, and bending deformations and cracks.

- Journal wear. The journal wear on the main crankshaft journal and connecting rod journals is uneven and has a certain regularity.

- The crankshaft can be bent and deformed by torsion. When we say that the crankshaft bends, it means the coaxiality of the main journal exceeds 0.05mm. The crankshaft is said to twist if the distribution angle error is greater than 30 degrees for the connecting rod journal.

- of the crankshaft. Cracks in the crankshaft are most common at the transition between the journal and crank and at the oil hole.

Maintenance on the Engine crankshaft

The main inspections of an engine crankshaft are crack inspection, deformation, and wear inspection.

(1) Inspection and repair of cracks. Check for cracks after cleaning the crankshaft. Crack inspection can be done using a dye penetrant or magnetic flaw detector. If the crankshaft has cracks, it is generally scrapped and replaced.

(2) Maintenance of crankshaft bend. Inspection of bending deformations should be done based on a common axis at both ends of the main journals, and the radial error of the central journal. Place the main journals of both crankshaft ends on the V block of the inspection plates, and place the dial indicator on the middle main magazine. Rotate the crankshaft slowly one full circle. If the dial indicator Swing Difference value is greater than 0.15mm then pressure correction is required. If the runout error is below this limit, then it can be corrected by grinding the main journal.

Cold press correction or percussion correction can be used to correct the bending deformation.

WHY CHOOSE US AS YOUR TRUCK PARTS SUPPLIER IN CHINA

Professional

we are a professional truck parts supplier, and wholesale, Manufacturer in China with more than 15 years of export experience, and we have more than 5,000 customers around the world

Affordable

We have a stable and strong supply chain, with a great advantage of the prices and lead time, our cooperated brands include Cummins, Foton, also for Yuchai, Mahle, Fleetguard, Holset, BOSCH, DENSO

Fast

With sufficient stock, normally our engine parts and other truck body parts have the fastest delivery time, generally available within 2-15 days for different quantities.

Service

With the professional sales team and engineers team, we can answer your inquiry or question within 12 hours, For inquiry, just tell us your quality grade, OE part No and quantities

CONTACT US NOW

24 hours on line